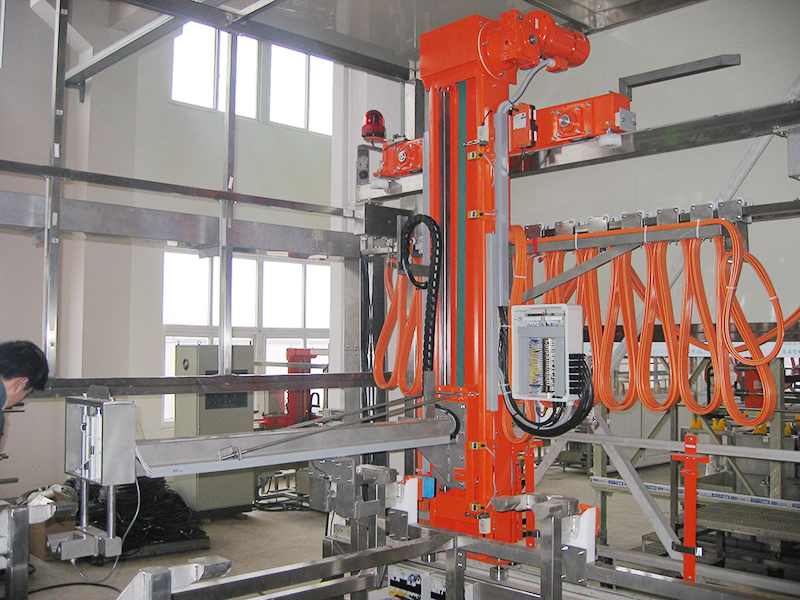

Fully Automated Copper Palladium Gold & Rhodium Iridium Plating Equipment (For Apple AirPods)

Keywords: electroless nickel-palladium gold, rhodium-ruthenium electroplating equipment, barrel plating equipment, anodizing equipment

In the field of anodic oxidation, it provides services for mainstream main engine factories in the industry, such as APPLE, DELL, HP, HUAWEI, ASUS, SONY, LENOVO, etc., grasps the operation process and process specifications of mainstream manufacturers, pays close attention to the new technology and development trend of anodic oxidation industry, and studies and updates anodic oxidation equipment to meet the needs of emerging processes.

Electroplating is an electrochemical process and also an oxidation-reduction process. The basic process of electroplating is to immerse the parts in a solution of metal salts as the cathode and a metal plate as the anode. After connecting to a DC power supply, the required coating is deposited on the parts

Not all metal ions can be deposited from aqueous solutions. If the side reaction of hydrogen ion reduction to hydrogen on the cathode dominates, it is difficult for metal ions to precipitate on the cathode. According to experiments, the possibility of metal ion electrodeposition from aqueous solution can be obtained from the periodic table. The anode is divided into soluble anode and insoluble anode, and most anodes are soluble anodes corresponding to the coating, such as zinc anode for zinc plating, silver anode for silver plating, and tin lead alloy anode for tin plating. However, a few electroplating processes use insoluble anodes due to difficulty in anode dissolution, such as acidic gold plating, which mostly uses platinum or titanium anodes. The main salt ions of the plating solution rely on adding a prepared standard gold containing solution. Addendum: Chromium plated anodes use insoluble anodes such as pure lead, lead tin alloys, and lead antimony alloys.

Previous Page

Message

Search

Contact Us

Add: No.8 Renmin Road, Yazhou Town, Hai'an, Jiangsu, China.

Tel: 0086-513-89079766

E-mail: jyc@jycplating.com.cn

Mobile website